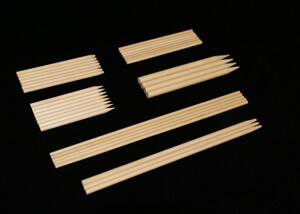

Custom Wooden Dowels

Manufactured in Bulk Quantities

Hardwood and softwood dowels manufactured to spec for commercial, industrial, and specialty use.

With multiple wood species available, we produce to your exact specifications, including dowel rods, barre dowels, skewers, flagpole dowels, and other specialty parts. Secondary machining options such as chamfering, drilling, fluting, or slotting are available.

PLEASE NOTE: BULK QUANTITIES ARE REQUIRED.

Available Dowels & Product Types

Available Diameters & Length Options

Species We Commonly Use

We regularly produce wooden dowels using species like White Birch, Maple, Oak, and Poplar, each chosen for their reliability in machining and finishing.

White Birch is often preferred for its smooth texture and clean grain, while maple and oak offer exceptional strength and durability. We also offer other species upon request, including softwoods and imported hardwoods, depending on your functional and aesthetic requirements.

All domestic species are harvested in a sustainable manner, as a matter of course, in US forestry regulations.

Secondary Operations to Match Your Specifications

We offer a wide range of secondary machining options to ensure your dowels are ready for use right off the line. These include drilling, tapering, sanding, chamfering, and slotting, among others. Whether you need dowels shaped to fit complex assemblies or custom ends for easier application, our team will machine each piece to your exact specifications.

Finishing Options and Custom Marking

In addition to shaping and turning, we offer a variety of finishing services to meet your visual and branding needs. Options include painting, staining, laser engraving, and ink printing—ideal for product identification, retail use, or color coding.

Let us know your requirements and we’ll recommend the most cost-effective solution.

Frequently Asked Questions (FAQs) for Wood Dowels

- All

- Dowels – Customization & Machining

- Dowels – Materials & Food-Safe Use

- Dowels – Ordering & Fulfillment

- Dowels – Product Capabilities

Yes. We can help you select lighter or denser species and match for color, texture, or grain.

You can submit your requirements through our quote form, call us directly, or email us. We’ll review your specs and respond with the next steps.

Our dowels are used in manufacturing, woodworking, cabinetry, fitness equipment, tool making, food packaging, education, retail display, and more.

Our minimum order generally varies depending on dowel type, size, and finish. Contact us for specifics to see if we’re a good fit for your needs.

Yes. We manufacture food-safe dowels and skewers with compliant coatings or unfinished options for clean handling. These are great for food service, packaging, or health applications.

We commonly use White Birch, Maple, Oak, Beech, Ash, Hickory, Pine, and Poplar. Other species are available depending on volume and availability.

We offer sanding, polishing, food-safe coatings, oiling, and staining. Dowels can be delivered raw or finished, depending on your needs.

Yes. We provide printing, stamping, and other branding options for identification, compliance, or retail display purposes.

Absolutely. We offer secondary machining including fluting, slotting, chamfering, end-drilling, tapering, cross-boring, and more. Let us know your exact requirements.

Yes. Common diameters range from 1/8” to 2”, but we can manufacture larger sizes on request. Standard lengths are 36” and 48”, with custom lengths up to 16’ in some species.

We produce round dowels, fluted dowels, skewers, barre dowels, tenoned dowels, flagpole dowels, and more. All are available in custom sizes, species, and configurations. Contact us for more information!