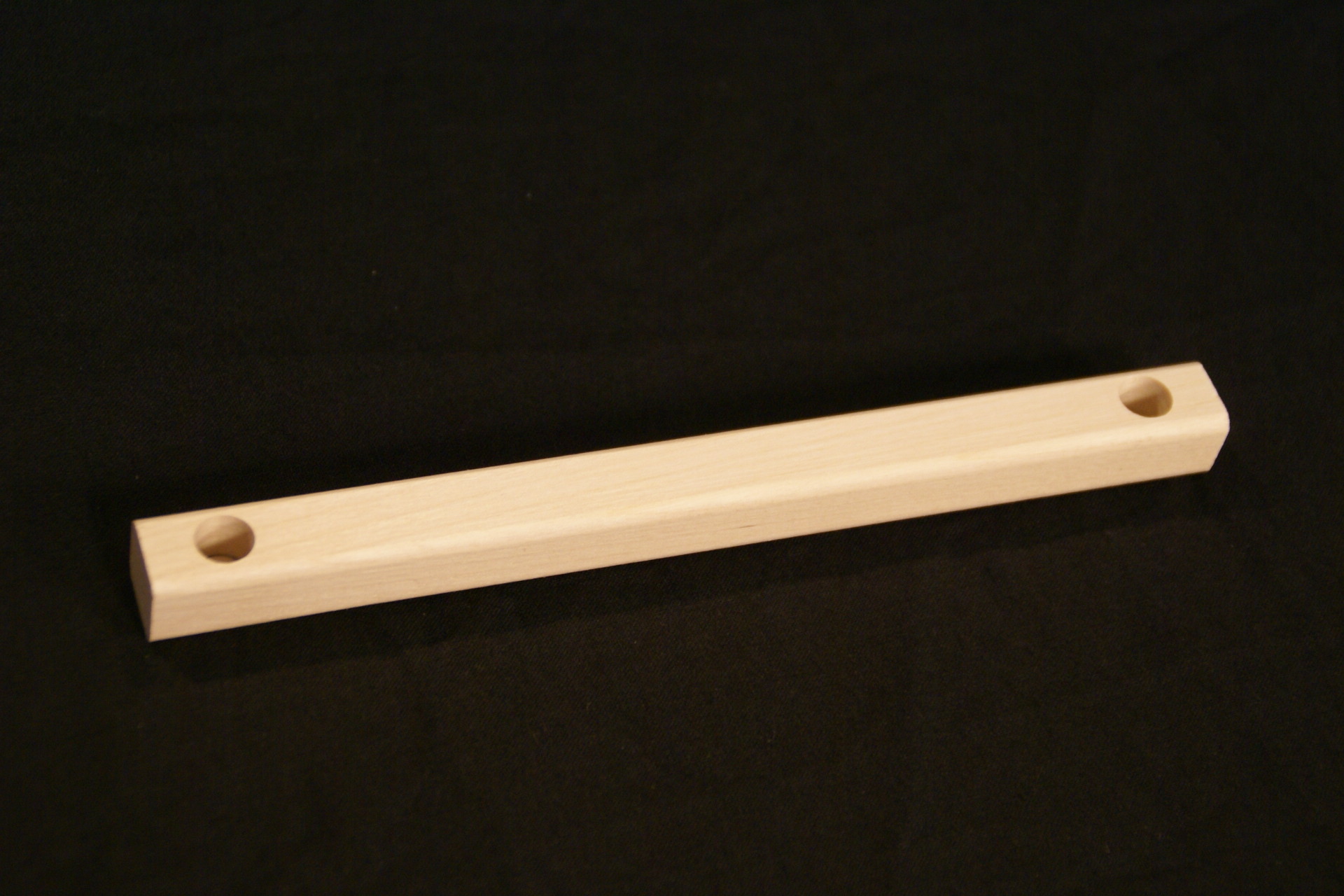

Custom Wood Moulding with Drilling and Shaping for High-Volume Manufacturing

Custom wood mouldings with drilling and shaping available for high-volume production or specialty orders.

Precision-Cut Custom Wood Mouldings with Secondary Operations

H.A. Stiles manufactures custom wood mouldings made to your exact design, dimensions, and material requirements. These components can be shaped, routed, drilled, tenoned, chamfered, or finished to match your downstream production or assembly process.

We specialize in high-volume orders and can incorporate multiple secondary operations during manufacturing to reduce your internal labor needs. Our mouldings are ideal for industrial components, specialty assemblies, or custom hardware integrations.

To see more options for wood mouldings and dimension, click here.

Send your drawings or part specs to get started.

Applications & Use Cases

Materials & Options

Request a Free Quote Today

Get mouldings engineered for your workflow. Let us machine, finish, and deliver exactly what you need—on time and to spec.